![neil]()

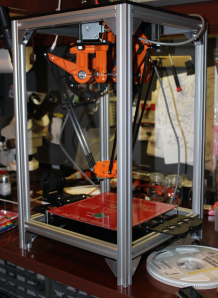

If we were running a contest to give away a trip to space for building the most innovative open hardware project a few years ago, the winner would inevitably be a 3D printer. Times have changed, 3D printing is reaching the limits of what can be done with simple plastic extrusion, and there are new hardware challenges to be conquered. One of the challenges facing hardware designers is the ability to create and assemble electronic circuits quickly. For that, there are a few pick and place machines being developed, the lowest cost being the FirePick Delta. It sells itself as a $300 pick and place machine borrowing heavily from the RepRap project, enabling tinkerers and engineers to assemble PCBs quickly.

[Neil Jansen] is the project lead for the FirePick Delta, and along with team members ranging from software developers in the bay area, to electronics technicians and high school students, they’ve created what will become the lowest cost and most capable pick and place machine available. Already the machine has tape feeders, tray feeders, a vision system, and modules to dispense solder paste. It’s an astonishing accomplishment, and were it not for some damage in shipping, we would have a video of [Neil] demoing the FirePick at Maker Faire NY.

In lieu of that, we do have a bio on [Neil] and what challenges he’s faced in building the FirePick. You can read that below, or check out their second demo video for The Hackaday Prize:

![]()

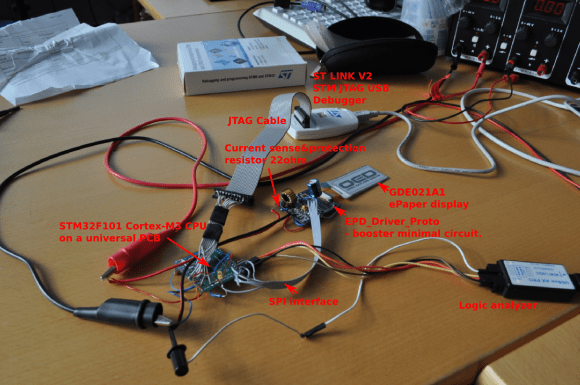

Robotics, and Extreme Circuit Boarding. The world does not yet recognize Extreme Circuit Boarding as a sport. But it basically consists of consuming large amounts of Red Bull, listening to loud Dubstep and Electro music, and designing crazy circuits, and then building them as quickly as possible when the boards and parts arrive. It’s extreme because you have to get the designs right on the first rev, with no rework. Kind of in the spirit of a hackathon or a Tattoo Inkmaster reality show. Since no one knows about this sport yet, I’m the unofficial world champion for 2014.

![]()

Aerospace, GPS / GNSS receivers, radios, autopilots, transponders, and collision avoidance systems, blah blah blah… My job is the hardware/software testing and verification of these boxes. These days I mostly write software, but at my last job, on a typical day, I’d be doing CAD in SolidWorks, schematic capture and pcb layout, writing embedded code, wiring test jigs and harnesses, requirements capture, and lots of other stuff. I only have a high school background, everything else is self-taught. Even though it’s a big stuffy company, I still get to do lots of different things, which keeps me happy. Our other team members have day jobs as well. Karl Lew works as a full stack software developer in Bay Area, California. Christian Lerche is an electronics technician in Denmark and works in a lab that works on locomotive electronics. Dayton Pid is our youngest member at 16 and is in high school. And Thomas Kilbride is in college at Indiana University.

My passion is basically the pursuit of reality through objectivism, critical thinking, and logic, and the propagation of those ideas leading by example, living by principles, appreciating the beauty of life, and taking personal accountability for my actions.

![]()

That honor almost went to my 2009 model MacBook Unibody recently. I have been using it as my main development platform for our Hackaday project, mostly while dual-booted into Windows 7. It’s extremely slow, sometimes requiring a few minutes to switch between different apps. It was maxed out at 4GB of RAM, and of course, every time I needed to dual-boot back to OSX to do photo editing or whatever, that was time lost. The battery has been dead for almost two years, so it’s pretty much anchored to the desk. I was almost about to take it out back and destroy it office-space style, while playing the obligatory “Still” from the Geto Boys from iTunes until it wouldn’t play any more. But instead, I hobbled together a new PC out of pieces I had lying around, and a new motherboard, CPU, and 16 GB of RAM. My productivity towards the HaD project since has probably tripled since I’ve gotten that taken care of.

![]()

I’m OS agnostic for the most part. On a typical day, I’m using Windows, OS X, BSD, Linux (both desktop and embedded), and occasionally esoteric RTOS platforms. I’m forced to run Windows for CAD, but it’s my least favorite to program on, and I agree with it the least philosophically. I use my MacBook for video editing, audio editing, photoshopping, and other graphic or A/V type stuff. Linux is awesome for embedded and server applications, but I can’t run Cubify Design on it, and I feel that the A/V apps on OS X are more matured and polished than anything available on Linux.

Linux would be my absolute favorite, but big corporations that make important pieces of software still won’t write programs for it, for some reason. In my dream universe, Microsoft would do like Apple did, and ditch their underlying operating system and .NET crap, and go with something POSIX (say, BSD) for their backend, thereby making it easier to write multi-platform software applications. They could even keep their crappy desktop look the same. But we all know they’d never, ever do that.

![]()

Hakko FX-888 soldering iron. I do everything from SMT to soldering 4-AWG wire, all with the same tip, out of laziness, and because I can. I couldn’t even imagine having to use a crappy soldering iron. Yet, I can’t say it makes me a snob, I’d have to have a $500 Metcal to say that.

![]()

I tend to gravitate towards the C-like languages, because I can pick one that suits any level of application I need. I routinely code in C/C++ for embedded stuff, but only really use the basic object-oriented things like classes and inheritance.

I’m starting to really like Javascript, it’s so ubiquitous and useful for high-level stuff, even if it’s a decidedly evil language. And I actually really like the concepts and paradigm of Java, even if it never seemed to work well in practice. I don’t really like Python even though I use it occasionally (the tabs and general treatment of whitespace bugs me). I also have an aversion to Perl, Lisp, Ruby, Haskell, Clojure, etc. Not because they’re bad. But because I don’t have the time to understand them, and they make the open source software ecosystem a fragmented mess.

![]()

- Create an open-source micro-factory, capable of creating amazing things locally and sustainably.. Ideally this is what Karl and I hope FirePick will evolve into. We see this as the logical progression of 3D fuse-filament printing, 3D metal printing, laser cutting, and SMT component assembly. If we can make it profitable for companies to at least make prototypes and small runs in America (or pretty much any other country for that matter), rather than everything coming from China, then we can say that we’ve done something truly empowering.

![2000px-HAL9000.svg]() “Hard” Artificial Intelligence (as opposed to the status quo “soft” AI). When I was a kid, I dreamed of pioneering in this field. Google claims to be working on this sort of stuff. These days, I’d be happy to be a cog in the wheel of some grand decades-long project to accomplish true AI.

“Hard” Artificial Intelligence (as opposed to the status quo “soft” AI). When I was a kid, I dreamed of pioneering in this field. Google claims to be working on this sort of stuff. These days, I’d be happy to be a cog in the wheel of some grand decades-long project to accomplish true AI.- I have to at some point finish a few pointless projects that I put off to work on this project… If I get the pick and place working well, then these will be a slam dunk. I want to finish my Nixie Tube wrist watch, that uses some Burroughs B-4998 tubes, aka, the smallest Nixie tubes in the world. Second, I want to make a really tiny robot (40mm x 40mm) with two wheels and a camera, that can sort a pile of M&Ms by color. Hopefully with a powerful ARM processor and lots of sensors, running SLAM technique, kalman filtering, etc. Third is a telepresence robot with two robotic arms and gimbal stereo vision on a segway syle inverted pendulum, controlled with a LEAP motion controller and an Oculus Rift. Then I could just mail my artificial self around the world and see cool places, and get to interact with stuff, while staying on schedule.

![]()

I would say that almost all DIY pick and place machines were created by someone who had to manually place lots of SMT components onto circuit boards, all by hand, probably with tweezers and a microscope if they were lucky. Most people find the process of doing it by hand very tedious. Many of them, myself included, have decided to engineer their way out of the problem by building some sort of homebrew machine to make the process faster and less error-prone. I’ve seen countless DIY pick and place machines, both manual and automatic, on the front page of Hackaday over the years. They all shared a common idea and problem, and most of them shared a similar fate. The DIY machines were never completed, because the people who built them were smart and busy with whatever project they needed the placement machine for. The problem was that the their DIY machine was just a means to an end, it was never an end goal for them. That’s where our machine differs. FirePick Delta is our only project, that we plan on working on for many years to come. We plan on refining it, and adding new SMT component feeders and other modular tools. And eventually, if everything works out, we’ll probably make the world’s first open-source SMT assembly line, with reflow ovens, conveyor belts, and stencil printers, all released under open source HW and SW licenses.

I’ve actually had the idea to use a delta mechanism for pick and place applications since some time around 2003, but didn’t have the manufacturing resources to build it. Around January 2014, a friend from a DIY forum asked me if I wanted to borrow and put together a kit for a RepRap Huxley 3D printer. I built it in a weekend, and quickly built five Prusa Mendel i2’s on it. One of those Prusa i2’s printed parts for my FirePick Delta prototype, which will hopefully print other FirePick Deltas one day. It’s incredibly cool when you think that the little eMaker Huxley was actually printed from other machines, that were printed from machines, that trace their way back to the first Darwin 3D printer, invented by Adrian Bowyer… which was itself printed from a Stratasys in Bath University, UK. So the hundreds and/or thousands of machines that I’ll be building over the next few years can all trace their heritage back to the original Darwin (the eMaker came with a certificate and everything, so I’ll likely have certificates for mine as well). The ideas of robots making robots intrigues me. They sort of have a pedigree, which is really neat.

Anyway, I had just assembled the first prototype of the FirePick Delta (back then codenamed Project Bismuth), about a day or two before the Hackaday Prize was announced. I was probably one of the first people to create a project after the contest was announced, because i remember frantically typing it out that night. The timing couldn’t have been better. We had always intended to keep it open source, but entering it for the Hackaday Prize sure has forced us to do the dirty documentation work that no one ever does. Kudos for having a requirement to do a system-level diagram. That’s one thing that I’ve rarely seen from an open source hardware project, but is sorely needed.

![]()

I could use some advice on where to find a good web app developer with node.js, Bootstrap, AngularJS, and Express skills, that would work for free and has lots of time to devote :) We had originally intended to have our html5 gui for the pick and place machine completed by now, but we didn’t take into account was how hard web app development really is, and how few people out there really have a mastery of it. We’re stuck with a Java Swing UI instead, for the PnP functionality :(

![]()

I was really intrigued by the metal 3D printer that was one of the first projects to be tagged with TheHackadayPrize. I think it would have required a crazy amount of metallurgy skills to pull off successfully, and I’m not sure they had said skills, but the concept was still really cool.

![]()

We actually have an incredibly complicated project, compared to say, OpenMV (which we love by the way). We’ve had problems with our delta arm linkages, backlash / accuracy problems, Hierarchical BOM generation, and feeder problems. However, we’ve got some really innovative ways to mitigate them that will hopefully be documented on our site by the Sept 29th milestone. We’d be a month further along if we didn’t have hundreds/thousands of BOM items to document, so, uh, thanks for making us do all of that :)

![]()

Thanks to the FirePick Delta core team, and all the people who skulled our project and believe in our idea. You guys rock.

Filed under:

3d Printer hacks,

The Hackaday Prize ![]()

![]()

The project featured in this post is an entry in

The project featured in this post is an entry in  Pick and Place machines are one of the double-edged swords of electronics.They build your boards fast, but if you don’t have everything setup perfectly, they’ll quickly make a mess. A pick and place can’t grab a resistor from a pile and place it – so far only humans can pull that one off. They need parts organized and oriented in reels or trays.

Pick and Place machines are one of the double-edged swords of electronics.They build your boards fast, but if you don’t have everything setup perfectly, they’ll quickly make a mess. A pick and place can’t grab a resistor from a pile and place it – so far only humans can pull that one off. They need parts organized and oriented in reels or trays.

The project featured in this post is

The project featured in this post is

“Hard” Artificial Intelligence

“Hard” Artificial Intelligence

If you’re building a pick and place machine, or even just a vacuum pen, you’ll need some way to pick up tiny part. This means something that sucks, aquarium tubing, and everything that goes with that. A few months ago, [Wayne] found an interesting device called a Micro Blower that will blow small amounts of air from a small, lightweight device. A few modifications later,

If you’re building a pick and place machine, or even just a vacuum pen, you’ll need some way to pick up tiny part. This means something that sucks, aquarium tubing, and everything that goes with that. A few months ago, [Wayne] found an interesting device called a Micro Blower that will blow small amounts of air from a small, lightweight device. A few modifications later,  While some other DIY pick and place setups we’ve featured use fairly exotic setups

While some other DIY pick and place setups we’ve featured use fairly exotic setups

When you are doing a bunch of boards that have a lot of components, it can quickly get tiring to place all the components by hand. One method of making it easier is the vacuum tip instead of tweezers. The idea here is to get an aquarium pump and set its direction so it is sucking. Then put a syringe on the end of a tube and put a small hole where the thumb will be. Now when you put the finger over the hole, the syringe needle will suck up a part. Move the part to your destination and release your thumb and the vacuum seal will be broken, releasing the part onto the PCB. This is good for pulling the part directly out of the tape where tweezers can’t reach. We’ve covered a few of these

When you are doing a bunch of boards that have a lot of components, it can quickly get tiring to place all the components by hand. One method of making it easier is the vacuum tip instead of tweezers. The idea here is to get an aquarium pump and set its direction so it is sucking. Then put a syringe on the end of a tube and put a small hole where the thumb will be. Now when you put the finger over the hole, the syringe needle will suck up a part. Move the part to your destination and release your thumb and the vacuum seal will be broken, releasing the part onto the PCB. This is good for pulling the part directly out of the tape where tweezers can’t reach. We’ve covered a few of these  The next step is a strange hybrid between man and machine. It’s a contraption that holds the PCB in place and has a hand rest that moves on linear rail in the X and Y directions, and sometimes has a vacuum needle as well, and trays for reels or loose components. It doesn’t have any brains; those are provided by the operator. The operator can rest their hand on the moving pad as they direct it to go pick up a part, then move to place it. It just alleviates the physical burden on the person doing the component placement, but doesn’t really save much time. It’s hard to think of a good use case for this level of machine, though. Maybe a shop where they have to assemble small batches of different boards? Definitely not for high volume production of one board.

The next step is a strange hybrid between man and machine. It’s a contraption that holds the PCB in place and has a hand rest that moves on linear rail in the X and Y directions, and sometimes has a vacuum needle as well, and trays for reels or loose components. It doesn’t have any brains; those are provided by the operator. The operator can rest their hand on the moving pad as they direct it to go pick up a part, then move to place it. It just alleviates the physical burden on the person doing the component placement, but doesn’t really save much time. It’s hard to think of a good use case for this level of machine, though. Maybe a shop where they have to assemble small batches of different boards? Definitely not for high volume production of one board.